Laser machines have been used for more than 30 years to cut and engrave various materials.

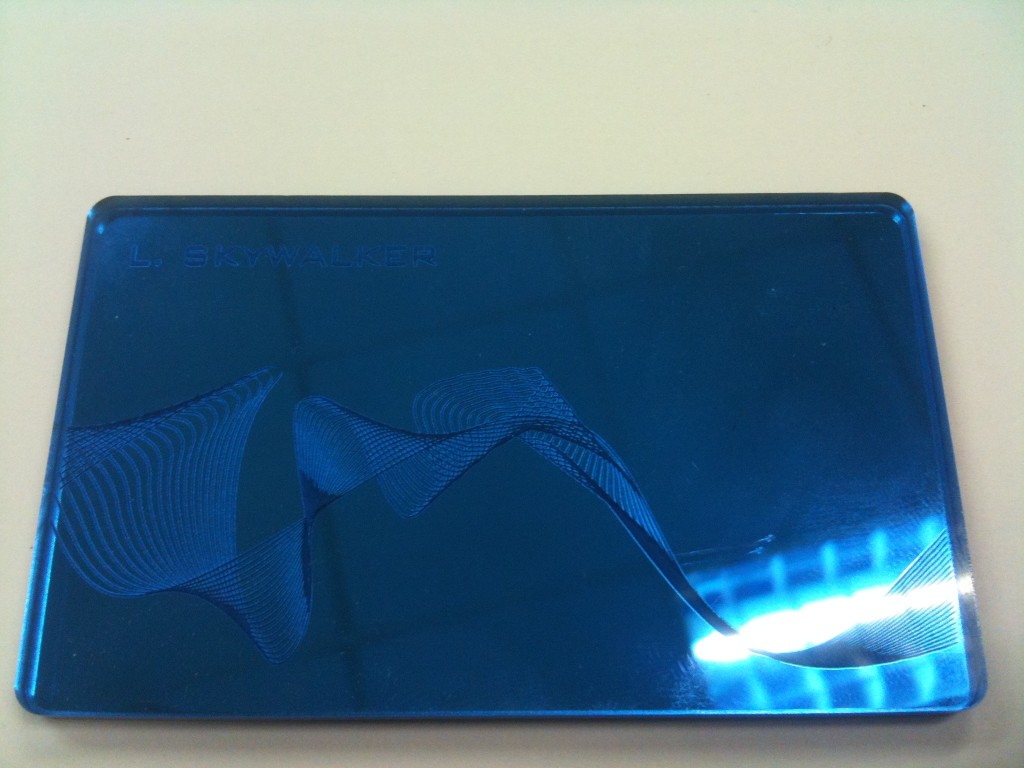

The most common application is laser cutting of acrylic for logos, lettering etc.

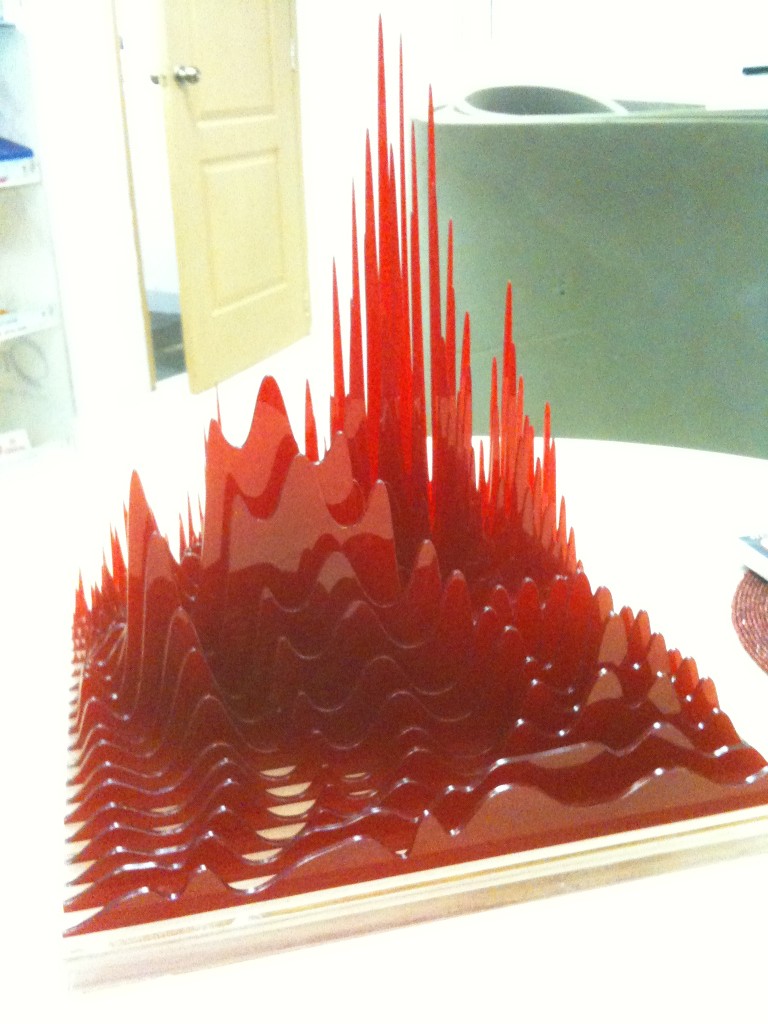

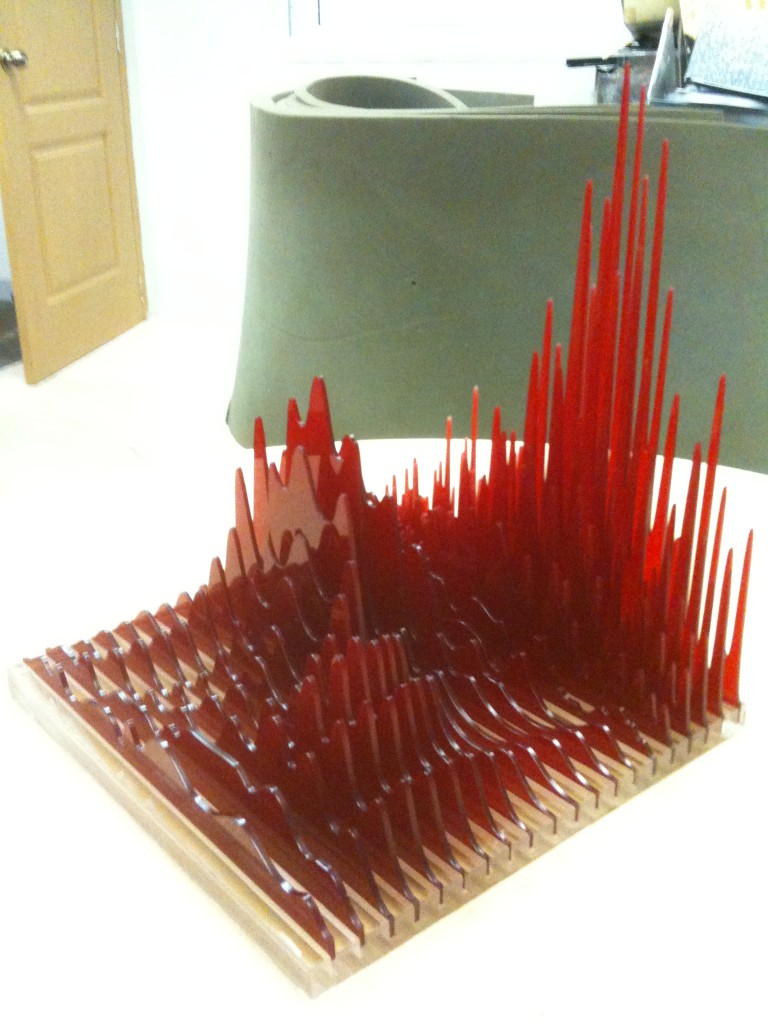

Another standard application is to do a surface engraving in plastic and wood of intricate pictures or text.

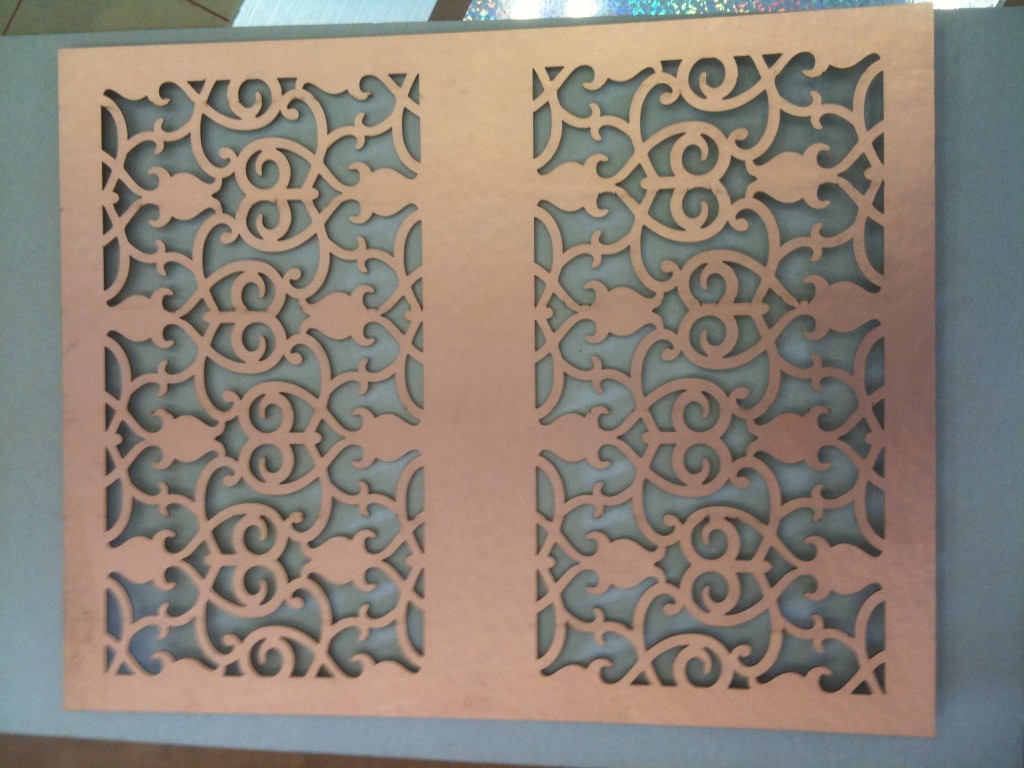

But recently laser cutting machines have found uses in many new markets, since they allow unique or small series of accurate shapes cut and have become more flexible in the materials they can process.

One of such application is for the fashion industry, where laser is used to cut and engrave intricate patterns and shapes in textile, leather, silk for luxe product line for clothes, jackets, shoes, handbags, purses, belts…

Started around 2005 by famous names like Galliano, it grows exponentially to reach mass market by 2011 with products from brands like Converse and articles in “grand public” fashion magazines like Marie Claire.

For more visual, I recommend this nice article with beautiful pictures of laser cut fashion and a quick history.

The main benefit is the almost real-time and no expensive set-up cost since the drawing is directly used by the computer to control the cut. With a cutting speed ranging from 10mm to 100mm per seconde, depending on the material and its thickness, the artist piece is delivered in a matter of minutes.

Such specialized laser cutting services, initially high-end, are now available at a reasonable price point, allowing new designers, artists and even individuals to leverage the same technology for their offering.

Some of the criteria that are criticals when looking for a laser cutting service for this industry requirements:

1) Laser power: when processing thick material, let’s say 2mm leather, you will need more than the 30W to 80W that the small shops have for regular acrylic cutting. The reason is the faster you can cut, the less you will have burn and distorted edges. And to cut fast, you need enough power. So the more power you have, the faster you cut, the less burnt edges;

2) Gas assist system: materials used in the fashion industry are for most of them flammable. Thus a strong gas assist with either clean filtered compressed air or neutral gas is a must to avoid fire risk and burnmarks;

3) Cutting area dimensions: while not important for small items, this is key for clothing in particular since the laser machine need to be able to accept your leather or textile material in its original width to optimize material and allow the cut as one piece.

At Plixo, we are one of the few in Singapore offering such laser cutting services. To do so, we have leveraged our industrial and engineering experience to built a laser machine dedicated to the needs of the decoration, artistic and fashion industry.

With 150W of Co2 power, controlled gas assist, working area of 1300mm x 900mm, filtering, industrial exhaust, dedicated software add-ons, a range of lenses, proprietary techniques and how to knowledge, we are able to do things that others will just tell you “Cannot!”.

For more information on this service, visit Plixo Laser cutting and engraving services.

And for Plixo’s other offer, visit Plixo: a Boutique Workshop.

Tags: laser, cutting, engraving, leather, fashion

Vandalized baby face

Vandalized baby face